AWS A5.24 Zirconium Welding Wire ER Zr2 (UNS R60702)

Tig-Mig Welding wire for Zirconium 702

AWS A5.24 Classification: ER Zr2

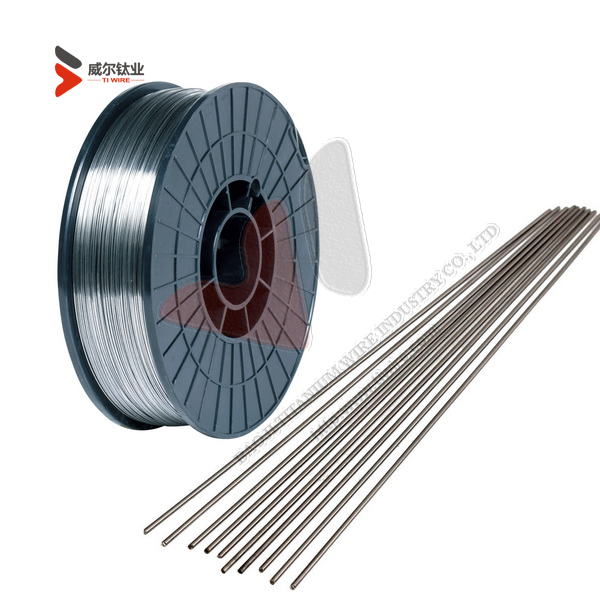

Shape: Straight, in spool

Surface Treatment: Polished

Specifications: AWS A5.24, ASTM B495

Size:

Diameter: From Ø 0.15mm - 6.0mm (Ø 0.006" - 0.236")

Length: From 914mm - 2000mm (Ø 36" - 78.75") -- For straight wire

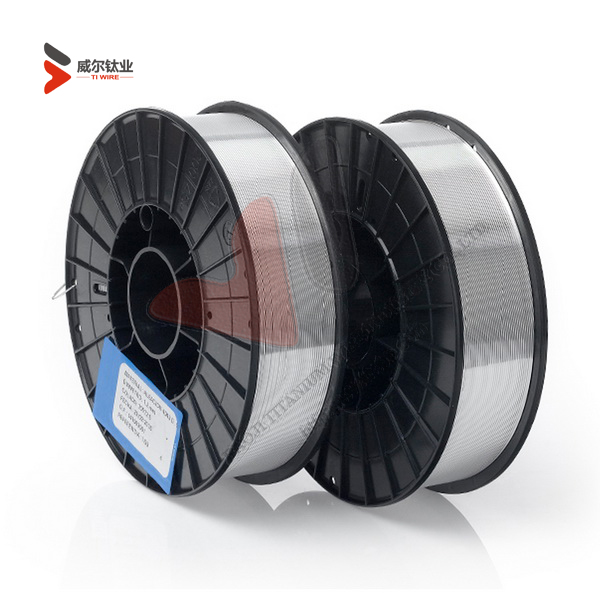

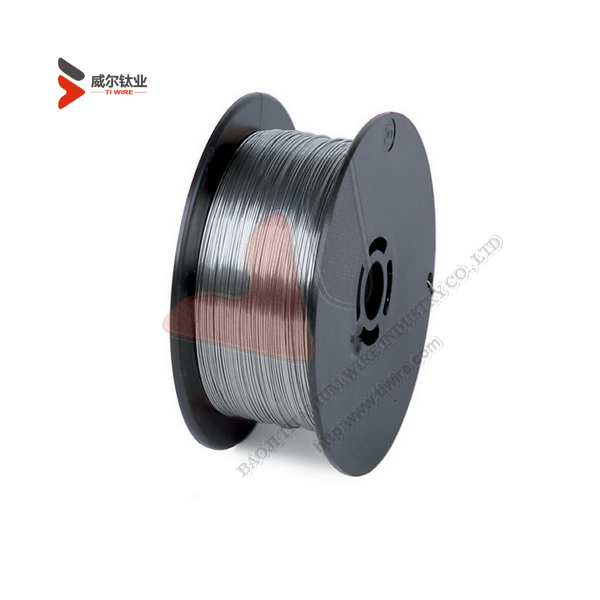

From 1kg - 10kgs per spool -- For Spool packing

Production Capability: 12 Metric Tons/month

Packing:

Straight: sealed with plastic bag in plastic box + plywood case.

In spool: carton box + plywood case.

As per customer’s requirement.

Delivery Time: 5-15 days

Shipping: By International Express(TNT, FEDEX, DHL, UPS, etc.), By Air, By Sea

![]() Zirconium Welding Wire ER Zr2.pdf

Zirconium Welding Wire ER Zr2.pdf

AWS A5.24 Zirconium Welding Wire ER Zr2 (UNS R60702)

Tig-Mig Welding wire for Zirconium 702

| CATEGORY | BTWI-BPTW Solid wires | ||||||||

| TYPE | Filler metal for Gas Tungsten Arc welding of Zirconium and Zirconium alloys | ||||||||

| APPLICATIONS | Zirconium Zr 702 is used widely in many industries for process equipment. Major applications include pressure vessels, heat exchangers, piping, tanks, shafts, mixers, and other mechanical equipment; valves; pumps; spargers; trays; and tower packing. | ||||||||

| PROPERTIES | Zirconium often is chosen for its resistance to corrosion from most organic and inorganic acids, salt solutions, strong alkalis, and some molten salts. It is especially suitable in many sulfuric, nitric, hydrochloric, and acetic acid applications. Backup Shielding. Backup shielding protects the molten root of the weld on the first pass and blankets the solidified weld during subsequent passes until the root surface temperature stays below 600 degrees F. Backup shielding also should be used on the back surface of sheet or plate less than 1/4 in. thick to prevent oxidation. Gas Requirements. Welding-grade argon (99.999 percent purity) usually is chosen for primary, secondary, and backup shielding, as well as for purging. Argon provides excellent arc stability, and because it is heavier than air, it blankets the weld and provides protection. Helium or argon/helium mixtures sometimes are used for torch shielding if added penetration is desired. Argon and helium mixtures also are occasionally employed for backup shielding and purging, in which helium's low density can effectively purge blind spaces. Gas Purity. Argon usually is purchased to 99.998 percent purity with a guarantee of less than 5 parts per million (PPM) oxygen, moisture, or total hydrocarbons. The dew point at the gas supply should not be more than -60 degrees F (-51 degrees C). | ||||||||

| CLASSIFICATION | AWS | A5.24: ER Zr 2 | |||||||

| UNS R60702 | |||||||||

| SUITABLE FOR | Welding Zirconium alloys in general but also for successfully weld zirconium to titanium, tantalum, niobium (columbium) and vanadium however the weld metal will be stringer and less ductile than the base metals. | ||||||||

FILER METAL WEIGHT %

| C | O | H | N | Ha | Zr + Ha | Cr + Fe |

| <0.03 | 0.11-0.15 | <0.005 | <0.015 | <4.50 | >99.0 | <0.20 |

MECHANICAL PROPERTIES

| Heat | RP0,2 | Rm | A | Impact Energy (J) ISO-V | Hardness | ||

| Treatment | (psi) | (psi) | (2") | -20°C | -40°C | -60°C | HRc / HV |

| AW | 30,000 | 55,000 | 16 | ||||

WELDING PARAMETERS / PACKING

| Welding Parameters | Packing | |||||

| Dia. (mm) | Length (mm) | Current (A) | kg / tube | |||

| 1,6 | 1000 | 80-150 | 5 | |||

| 2.0 | 1000 | 100-175 | 5 | |||

| 2.4 | 1000 | 130-200 | 5 | |||

| 3.2 | 1000 | 180-225 | 5 | |||

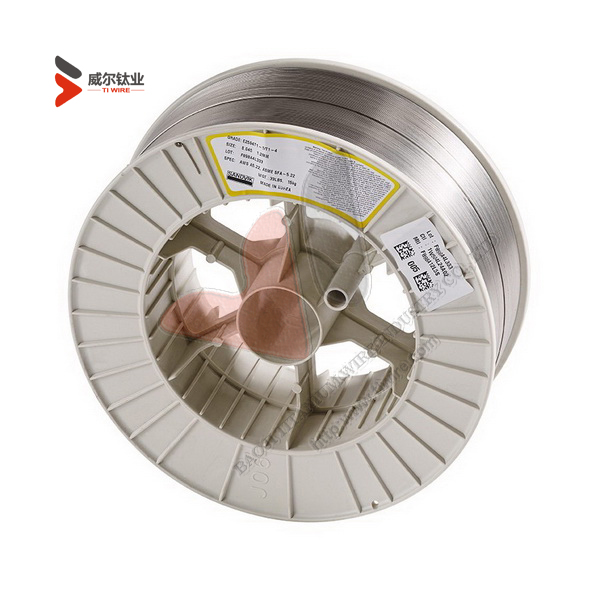

| SPOOLED WIRE | This aloy is also available as spooled wire on D-300 spools ranging from 0,8 till 1,6 mm. | |||||