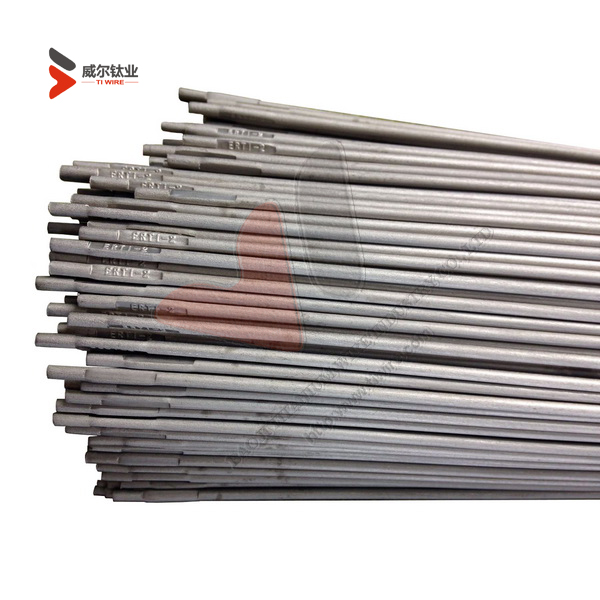

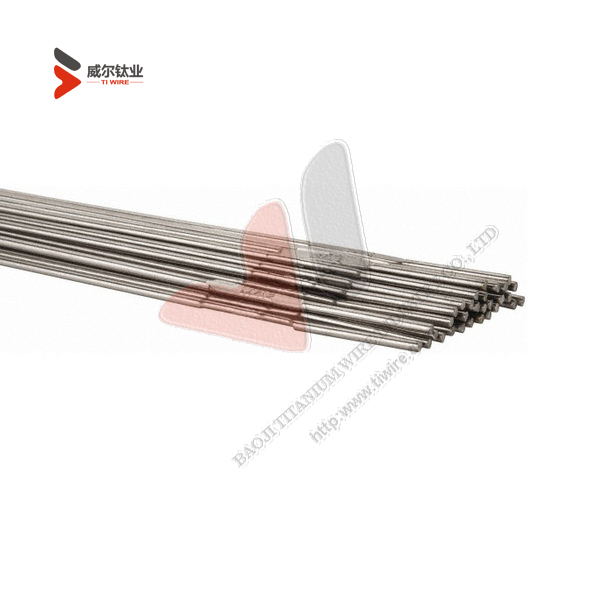

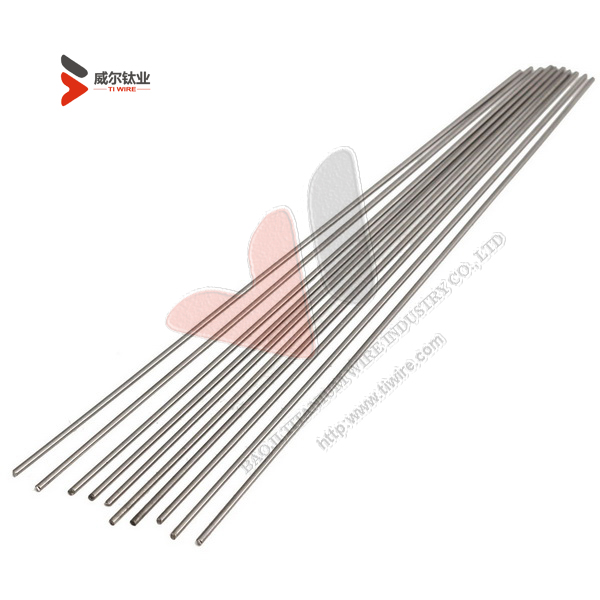

AWS A5.16 Straight Titanium Welding Wire ERTi-5 (Ti 6Al4V) Tig & Mig Welding wire for Alloyed Titanium Grade 5

AWS A5.16 Classification:

ERTi-5

Shape: Straight

Surface Treatment: Polished, Pickled

Specifications:

AWS A5.16, ASTM B863, AMS4951, AMS4954, ASTM F136

Size

Diameter: From Ø 0.15mm - 6.0mm (Ø 0.006" - 0.236")

Length: From 914mm - 2000mm (Ø 36" - 78.75") -- For straight wire

Stock Range:

Diameter Ø 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.0mm, 4.0mm

Length: 914mm, 1000mm

Production Capability:

72 Metric Tons/month

Packing:

Straight: sealed with plastic bag in plastic box + plywood case.

As per customer's requirement.

Delivery Time:

5-15 days

Shipping:

By International Express(TNT, FEDEX, DHL, UPS, etc.), By Air, By Sea

AWS A5.16 Straight Titanium Welding Wire ERTi-5 (Ti 6Al4V) Tig & Mig Welding wire for Alloyed Titanium Grade 5

Ti-Gr. 5: Recommended for high mechanical resistance applications up to 350° -400°C, it combines an ideal set of properties: high tensile strength, low density, toughness and ductility, weldability and machinability comparable to austeni1ic stainless steel.

Suitable to solution and precipitation heat treatments.

Ti-Gr. 5 eli: Ti6Al4V with extra low interstitial elements content, with enhanced ductility, typically used in the non aged condition for maximum toughness. Widely used for cryogenic devices as well as medical applications.

| Category | BTWI-BPTW Solid wires | ||||||

| Type | Solid Titanium based welding wire (Grade 5) with extreme high strenght. | ||||||

| Applications | Aerospace, marine, chemical plants, process plants, power generation, oil and gas extraction, medical and sports. | ||||||

| Properties | Excelent weldability, and can be heat treated to a higher strength or toughness. Grade 5 is used in aircraft components such as landing gear, wing spars, and compressor blades. Its corrosion resistance is generally comparable to Grade 2 and it is often used in corrosion service where higher strength is required, particularly in shafts, high strength bolting, and keys. The weld deposit is ductile and offers excellent corrosion resistance in oxidizing environments. The unique combination of mechanical strenght and corrosion resistance makes the alloy a prefered choice in many applications to prefend or solve problems. The wire is cleaned in a very special way to obtain porosity free and a ductile weld deposit. | ||||||

| Classification | AWS A 5.16: ER Ti 5 | ||||||

| UNS: R56400 | |||||||

| Suitable for | Titanium grade 5, UNS R56400, AMS 4954 | ||||||

Chemical Compositions:

| C | O | N | H | Fe | Al | V | Pd |

| < 0.05 | 0.12 - 0.20 | < 0.03 | < 0.015 | < 0.22 | 5.5 - 6.7 | 3.5 - 4.5 | -- |

Mechanical Properties:

Heat Treatment | RP0,2 (N/mm2) | Rm (N/mm2) | A5 (%) | Impact Energy (J) ISO-V | Hardness | ||

| -20°C | -40°C | -60°C | HRc/HV | ||||

| >890 | >810 | -- | -- | -- | -- | -- | |

Weld Parameters/packing:

| Welding Parameters | Packing | ||||||

| Dia. (mm) | Length (mm) | Current (A) | kg/tube | ||||

| 1.6 | 914 -1000mm | 5 | |||||

| 2.0 | 914 -1000mm | 5 | |||||

| 2.4 | 914 -1000mm | 5 | |||||

| 3.0 | 914 -1000mm | 5 | |||||

| 3.2 | 914 -1000mm | 5 | |||||

| 3.5 | 914 -1000mm | 5 | |||||

| 4.0 | 914 -1000mm | 5 | |||||

Note: Also available as spooled wire :0.8 mm, 1.0 mm and 1.2 mm (D-100/D-200/D-300) | |||||||