AWS A5.16 Titanium Welding Wire ERTi-7

Tig-Mig Welding wire for Alloyed Titanium Grade 7

AWS A5.16 Classification:

ERTi-7

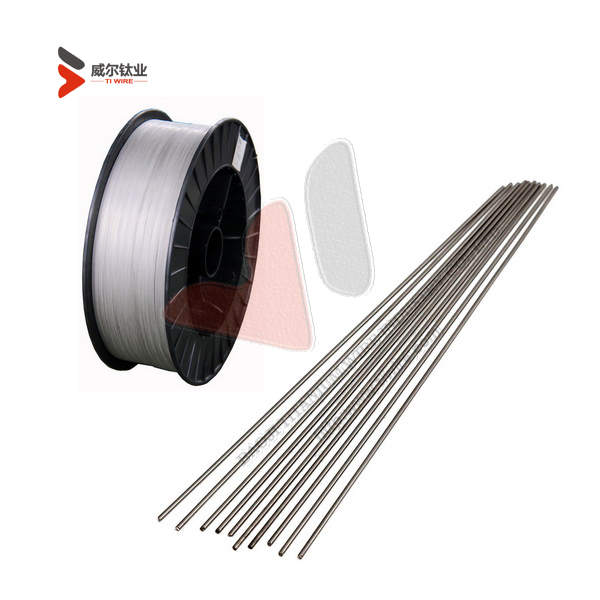

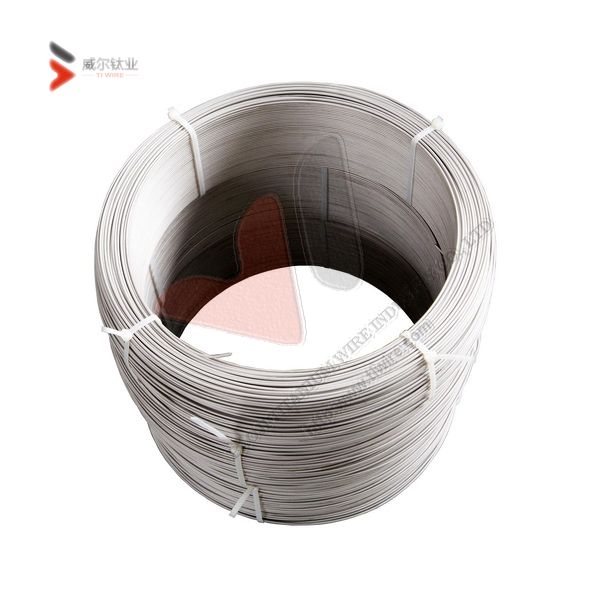

Shape:

Straight, in spool

Surface Treatment:

Polished, Pickled

Specifications:

AWS A5.16, ASTM B863, AMS4951, AMS4954, ASTM F136

Size

Diameter: From Ø 0.15mm - 6.0mm (Ø 0.006" - 0.236")

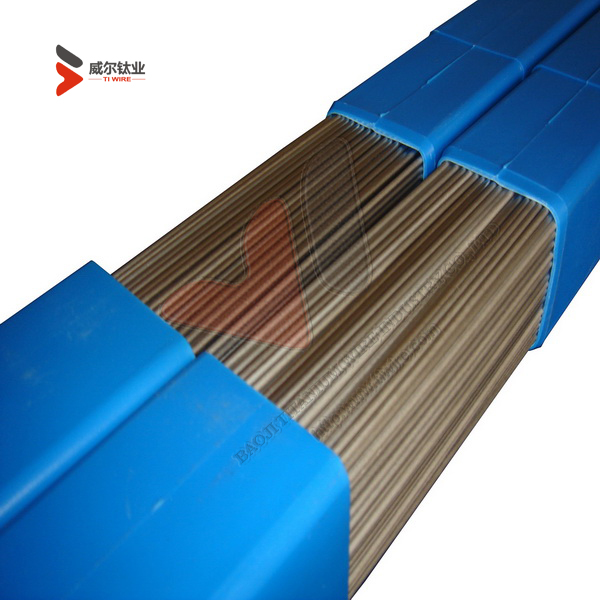

Length: From 914mm - 2000mm (Ø 36" - 78.75") -- For straight wire

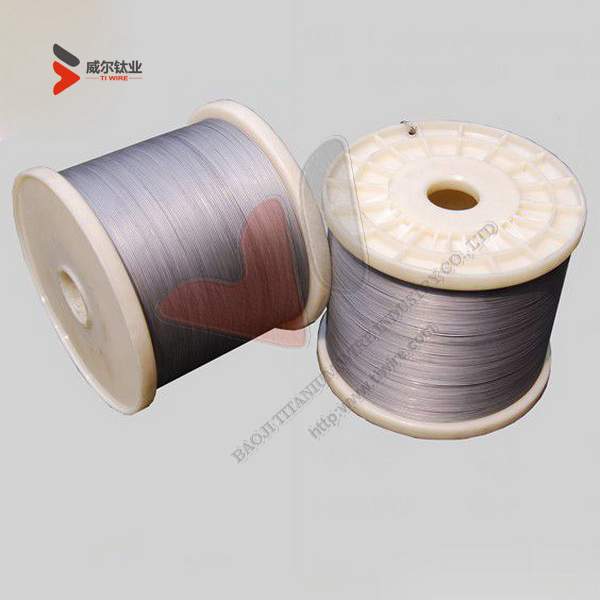

From 1kg - 30kgs per spool -- For Spool packing

Production Capability:

72 Metric Tons/month

Packing:

Straight: sealed with plastic bag in plastic box + plywood case.

In spool: carton box + plywood case.

As per customer’s requirement.

Delivery Time:

5-15 days

Shipping:

By International Express(TNT, FEDEX, DHL, UPS, etc.), By Air, By Sea

AWS A5.16/SFA-5.16 Titanium Welding Wire ERTi-7

| Category | BTWI-BPTW Solid wires |

| Type | Solid drawn Titanium Grade 7 welding wire |

| Applications | Grade 7 has the same mechanical properties as Grade 2. The 0.12 wt% palladium addition improves corrosion performance under mildly reducing conditions or where crevice or under-deposit corrosion is a problem. ERTi-7 can be considered for welding Grade 2 or 16 where improved corrosion performance is desired. |

| Properties | The weld deposit is ductile and offers excellent corrosion resistance in oxidizing environments. The unique combination of mechanical strenght and corrosion resistance makes the alloy a prefered choice in many applications to prefend or solve problems. The wire is cleaned in a very special way to obtain porosity free and a ductile weld deposit. |

| Classification | AWS A 5.16: ER Ti 7 |

| UNS: R52401 | |

| Suitable for | Titanium grade 7, Grade 2, Grade 16 |

Welding Deposit Weight %

| C | O | N | H | Fe | Al | V | Pd |

| < 0.03 | 0.08 - 0.16 | < 0.015 | < 0.008 | < 0.12 | - | - | 0.12 - 0.25 |

Mechanical Properties:

Heat Treatment | RP0,2 (N/mm2) | Rm (N/mm2) | A5 (%) | Impact Energy (J) ISO-V | Hardness | ||

| -20°C | -40°C | -60°C | HRc / HV | ||||

| as welded | 275 | 400 | 20 | -- | -- | -- | -- |

Welding Parameters/Packing:

| Welding Parameters | Packing | ||||||

| Dia. (mm) | Length (mm) | Current (A) | kg / tube | ||||

| 1.0 | 914 -1000mm | 5 | |||||

| 1.2 | 914 -1000mm | 5 | |||||

| 1.6 | 914 -1000mm | 5 | |||||

| 2.0 | 914 -1000mm | 5 | |||||

| 2.4 | 914 -1000mm | 5 | |||||

| 3.2 | 914 -1000mm | 5 | |||||

| 4.0 | 914 -1000mm | 5 | |||||

| Note: Also available as spooled wire :0.8 mm, 1.0 mm and 1.2 mm (D-100 / D-200 / D-300) | |||||||

![]() Titanium Welding Wire ERTi-7.pdf

Titanium Welding Wire ERTi-7.pdf