AWS A5.16 Titanium Welding Wire ERTi-1

Tig-Mig Welding wire for Titanium Grade 1

AWS A5.16 Classification:

ERTi-1

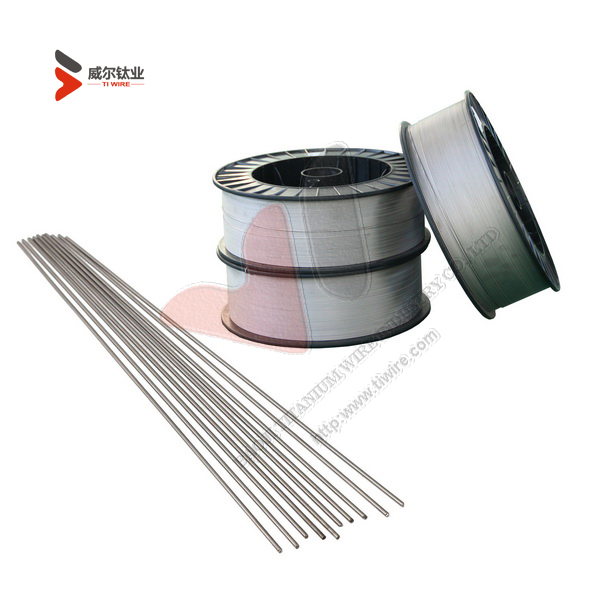

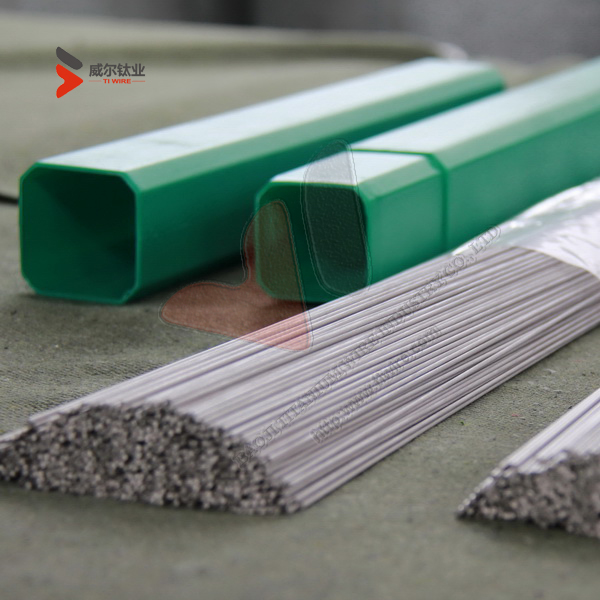

Shape:

Straight, in spool

Surface Treatment:

Polished, Pickled

Specifications:

AWS A5.16, ASTM B863, AMS4951, AMS4954, ASTM F67

Size

Diameter: From Ø 0.15mm - 6.0mm (Ø 0.006" - 0.236")

Length: From 914mm - 2000mm (Ø 36" - 78.75") -- For straight wire

From 1kg - 30kgs per spool

Production Capability: 72 Metric Tons/month

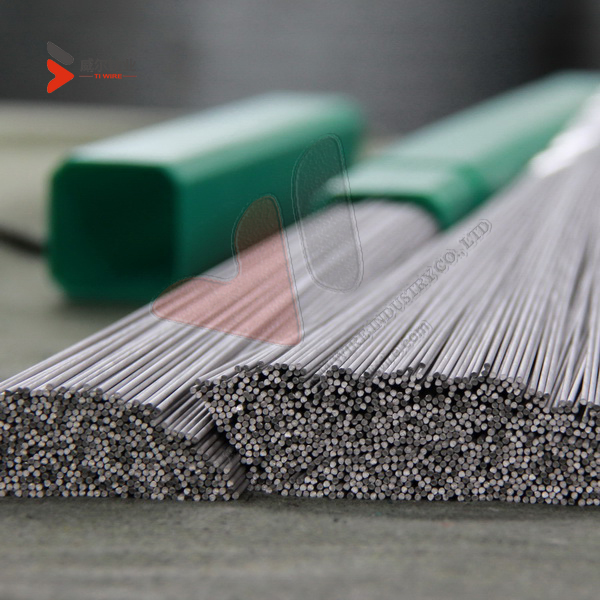

Packing:

Straight: sealed with plastic bag in plastic box + plywood case.

In spool: carton box + plywood case.

As per customer’s requirement.

Delivery Time:

5-15 days

Shipping:

by International Express(TNT, FEDEX, DHL, UPS, etc.), By Air, By Sea

AWS A5.16/SFA-5.16 Titanium Welding Wire ERTi-1

| Category | BTWI-BPTW Solid wires |

| Type | Solid Titanium welding wire Grade 1 (purest grade) |

| Applications | ERTi-1. Grade 1 is the lowest strength unalloyed (or Commercially Pure—CP) grade. Grade 1 is used in applications where ductility is paramount, such as explosive cladding, loose linings, expanded metal, and deep drawing applications. It is also used in electrolytic applications like coated anode substrates for production of chlorine and sodium chlorate. |

| Properties | The weld deposit is ductile and offers excellent corrosion resistance in oxidizing environmentsThe purity and corrosion resistance makes the alloy a prefered choice in many applications to prefend or solve problems. The wire is cleaned in a very special way to obtain porosity free and a ductile weld deposits. |

| Classification | AWS A 5.16: ERTi-1 |

| UNS: R50100 | |

| Suitable for | ER Ti-1 is the purest grade and is suitable for welding Titanium grade 1, 2, 3 and 4. With the restriction that the mechanical properties are much less than Grade 2, 3 and 4. The weld deposit is ductile and offers excellent corrosion resistance in oxidizing environments. This alloy finds his applications in chemical industry and offers excellent Weldabillity. |

Weld deposit weight %

| C | O | N | H | Fe | Al | V | Pd |

| < 0.03 | 0.03-0.10 | < 0.012 | < 0.005 | < 0.08 | -- | -- | -- |

Mechanical properties

| Heat Treatment | RP0,2 (N/mm2) | Rm (N/mm2) | A5 (%) | Impact Energy (J) ISO-V | Hardness | ||

| -20°C | -40°C | -60°C | HRc/HV | ||||

| as welded | 250 | 320 | -- | -- | -- | -- | -- |

Welding parameters / packing

| Welding Parameters | Packing | ||||||

| Dia. (mm) | Length (mm) | Current (A) | kg / tube | ||||

| 1.0 | 1000 | 5 | |||||

| 1.2 | 1000 | 5 | |||||

| 1.6 | 1000 | 5 | |||||

| 2.0 | 1000 | 5 | |||||

| 2.4 | 1000 | 5 | |||||

| 3.0 | 1000 | 5 | |||||

| 3.2 | 1000 | 5 | |||||

| 3.5 | 1000 | 5 | |||||

| 4.0 | 1000 | 5 | |||||

| 4.5 | 1000 | 5 | |||||

| 5.0 | 1000 | 5 | |||||

| 6.0 | 1000 | 5 | |||||

Note: Also available as spooled wire :0.8 mm, 1.0 mm and 1.2 mm (D-100/D-200/D-300)

![]() Titanium Welding Wire ERTi-1.pdf

Titanium Welding Wire ERTi-1.pdf